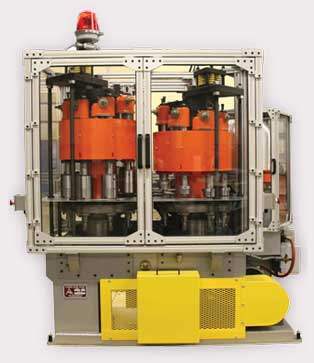

RLS Rotary Lug Machine

Description

The RLS is a high-speed rotary machine capable of producing lug (twist-off) caps. Basic configuration includes 3 work stations each having 8 tool locations which can be used, or left idle, depending upon desired production rates. Fully tooled, the RLS can produce at a rate of 800 caps per minute. The RLS is a modular design, allowing for easy custom configuration.

The main gearing is totally enclosed and runs in an oil bath. Lubrication fittings are provided for all key points to minimize wear. The RLS is provided with a 7.5 HP AC brake motor with variable frequency control. A PLC-based control package is available.

Operation

Station 1 performs a coax-curl wherein the shell is picked up and rolled against a rail to produce a coax radius on the shell. Roll position and pressure are fully adjustable. Sun and planetary gears are protected by a spun aluminum dome that also serves to retain the lubricating oil mist. Station 2 is the die-curl wherein the coaxed shell receives the initial curl. Station 3 is the curl-and-lug wherein the curl is finished and lugs are formed. The cam operated punch holders in the 2nd and 3rd stations are hardened, ground and run in hardened steel guide bushings. Tooling is adjustable through a 0.250 in. range and is protected by overload sensors which stop the machine.

Specifications

Technology Brief:

High speed, continuous rotary forming machine; basic configuration includes 3 work stations with 8 tool locations each.

Production Rate:

Max. 800 caps per minute.

Cap Size:

30mm – 89mm

Dimensions:

73” L x 50” W x 122” H; 5,000 lbs.

Utilities:

Electric service per customer’s requirements; minimal air required.